Rethinking design with 6D innovation

Incorporating ultimate flexibility into the industrial automation industry

Sign up for our 6D workshop

Dynamic grouping in a familiar setting

Watch as our 6D shuttles slide into formation, and dive further into PJM's universe of 6D. Get familiar with the ultimate solution that simplifies and upgrades your manufacturing setup using innovation and convenience.

How does 6D work?

- Shuttles with integrated magnets float across the surface of an electromagnetic motor segment

- The modular segments can be arranged freely in any desired shape or form

- Depending on the mix of shuttles, they can carry a load of 0.6 to 14 kg and reach a speed of up to 2 meters per second

- The shuttles can move in a two-dimensional space, tilt, and even rotate along three axes, all while controlling the height of levitation

- All of these options of movement provide the shuttles with six degrees of motion control freedom

A new technical era straight from our Innovation Lab

6D is a concept that we employ in our Innovation Lab - a creative environment where collaborative developments and new ideas are created. 6D provides new dimensions of adaptive manufacturing, making it ideal for smaller production batches with regular changeover of the products including different designs and dimensions.

Wish to know more about what unfolds in our Innovation Lab? Then click below.

An industry superhero

Due to the crucial hygienic advantages that 6D enables, the innovative technology is advantageous to employ within industries such as pharma and medico, where hygiene is key.

The frictionless movement allows the shuttles to flow with little to no contact with additional elements. This serves as a favor in the clean rooms, where maintenance of the transportation lines is kept to an absolute minimum.

In collaboration with our customers, we offer proof of concept solutions using 6D, which facilitates any project by enabling the front-end design step to reveal the outcome of the manufacturing setup. All illustrated with some swift movements.

Read more about front-end-design here.

INNOVATIVE OUTCOMES TO GAIN FROM USING 6D

The hovering, magnetic shuttles are designed to move according to an algorithm, simulating the transportation of elements in a production line.

What will you achieve with 6D?

- Great flexibility and high OEE (Overall Equipment Effectiveness): Several product variants can run on the same machine

- Ultra-fast line clearance

- Small, hygienic footprint on the machines: Pose as a great advantage in the clean rooms

- Large scalability: It is quick to switch from large to small batches (and vice versa)

- Quick setup and less maintenance due to less mechanical wear

- The software can quickly be converted to new processes with full product traceability

Optimize your manufacturing setup and minimize your carbon footprint

The multidimensional processing space that 6D introduces, allows for a combination of high shuttle density and infinite path flexibility which makes the machines and lines visibly smaller and increasingly more productive.

Exceeding the obvious advantages, 6D has several features that could benefit your production when integrated into your automation project:

- It saves space

- Zero wear and maintenance

- Full integration

- Intelligent shuttles and strict positioning

- Convenient setup

Essentially, 6D offers unlimited possibilities in machine design, which allows developers to focus on developing optimal machine processes and delivering top-notch productivity and outcomes.

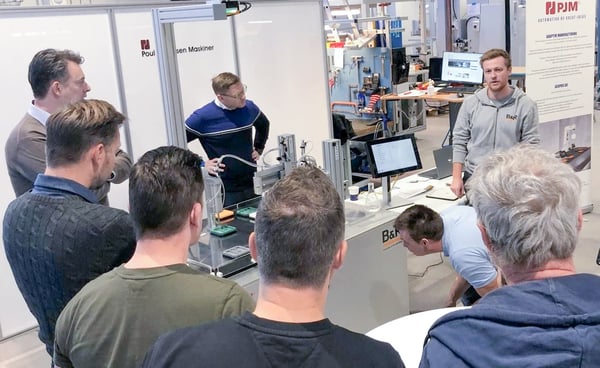

WATCH IT LIVE AT OUR 6D WORKSHOP

Do you want to watch the 6D technology up close and are you interested in knowing how this innovation can improve your production setup?

Then join us at our next workshop where we will demonstrate the flexibility and efficiency of 6D and look into the specific needs of your production.

We have done it before and it was a great success, click here to relive the whole thing or sign up for our 6D workshop through the form below.