Processing

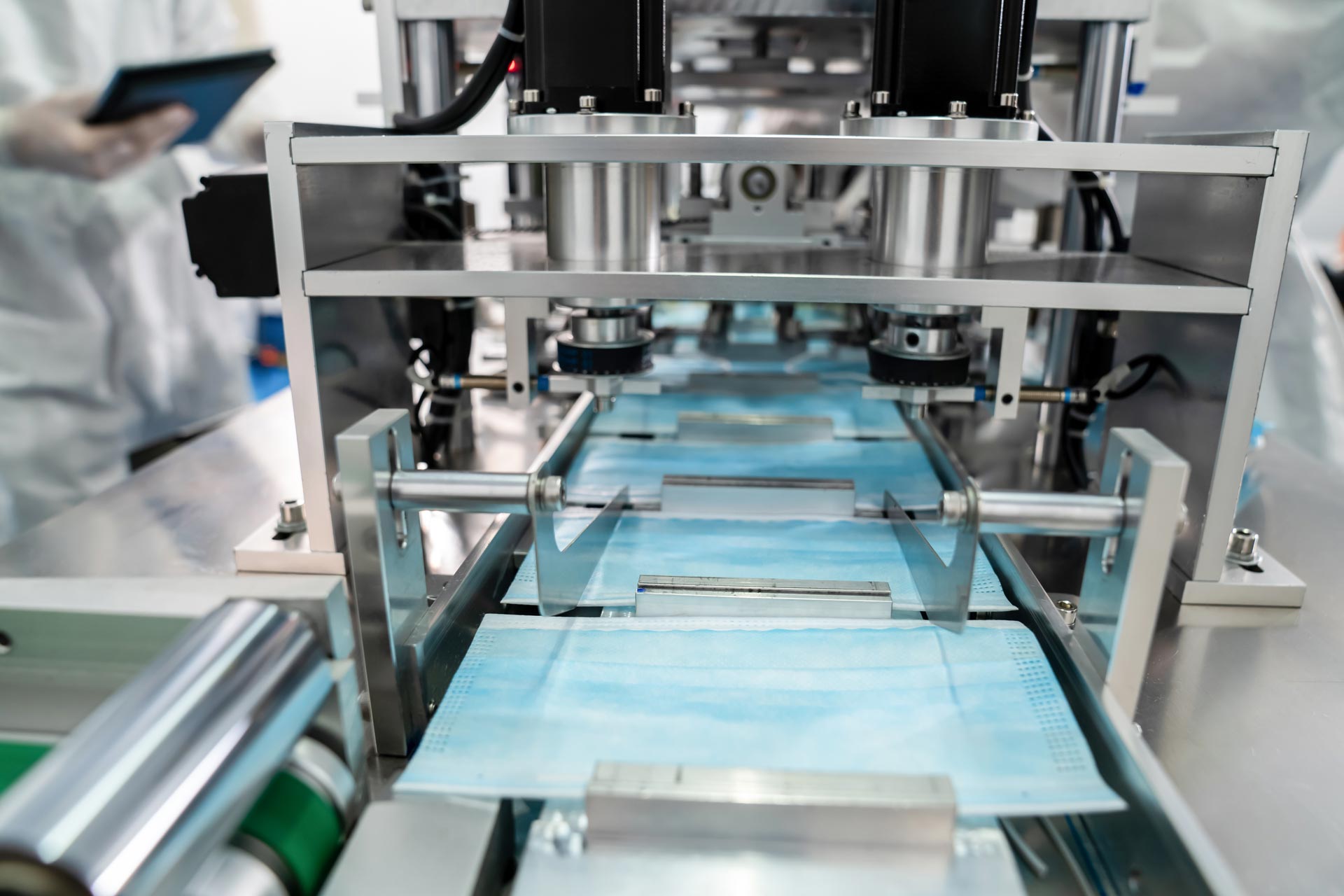

PJM processing solutions are used mainly in healthcare production and in industrial automation lines.

We specialize in high speed assembly solutions with small or medium-sized components for production of e.g. medical single-use devices and healthcare consumables. Our solutions are also widely found in electronics production, toy production and many other business areas as well.

We work closely with our customers to develop and integrate the right solution, often taking part in a development project from the early stages, where we can act as front-end consultants.

We ensure fast prototyping, proof-of-concept, conceptual design and add value by employing our experience from decades of automation projects. After installation, we carry out service and maintenance of the installed assembly solution.

Our expertise covers assembly processes such as:

-

Cutting/Punching

- Punching on catheters

- Laser stripping and cutting

- Impulse sealing and cutting

- Tube winding and cutting

- Foil welding and foil handling

-

Forming

- High speed tip forming on catheters

- Beading

- Straightening of capillary tube

-

Heat Treatment

- Oven curing (hardening)

-

Light Treatment

- UV treatment

- Corona treatment/surface tension elimination

-

Liquid/Gas Processes

- Coating/fluid handling

- Fluid mixing (ATEX compliant)

- Filling/Dosing of gases

- Filling/Dosing of liquids

- Surface Treatment

- Dipping and dapping

- Siliconization

-

Marking/Decoration

- Pad printing as integrator

- Micro Sticker application (high precision)

- Laser engraving

- Inkjet printing

- Removal of surface tension (corona)

Want to know more ?

Would you like to know more about we can help you with your next project?

Drop us a line !